High quality surface treatment begins with SAMWO grinding

Take you to know different

Sam Wo Polishing Materials (Guangdong) Company Limited, is solely owned by

Sam Wo Polishing Materials (Hongkong) Company Limited which was established in the year of 1992. We are one of the largest manufactures in China who are specialized in producing all kinds of polishing materials.

With dozens of years of experiences, we know how to adopt the state-of-the-art

technology in making a wide spectrum of sisal buff, sisal cord buffs, cotton buff, non-

woven web buffs, abrasive belt, abrasive cloth and polishing compounds. At the same

time, we've been producing sisal yarns, sisal twines and sisal cloth since 2007, to further

improve our competition ability and widen the product range.

We are dedicated in

supplying a wide variety of polishing materials at competitive prices and superb quality. We

would be very pleased to have you communicate with us for special design and

application problem. It would be our great honor in serving you to your greatest

satisfaction.

Creating Leadership in Polishing Field with Strength and Quality

SAM WO

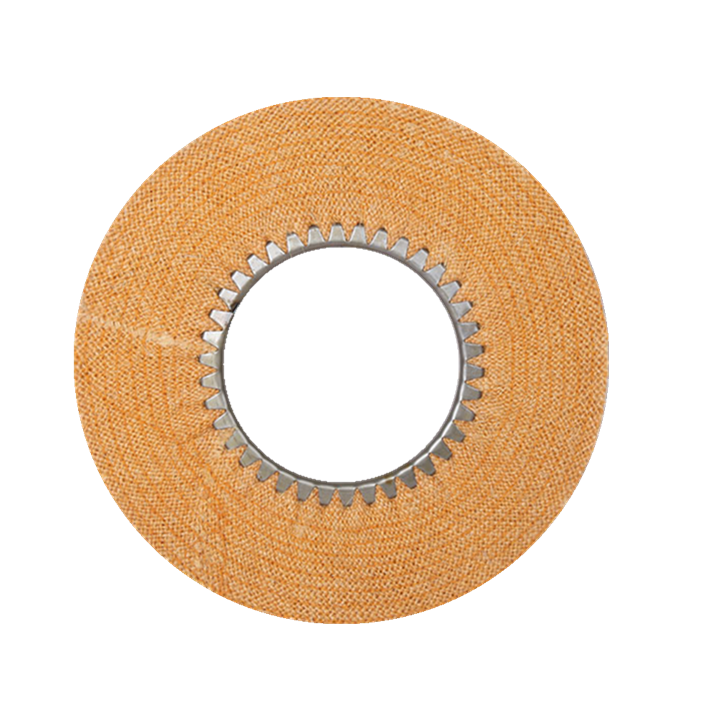

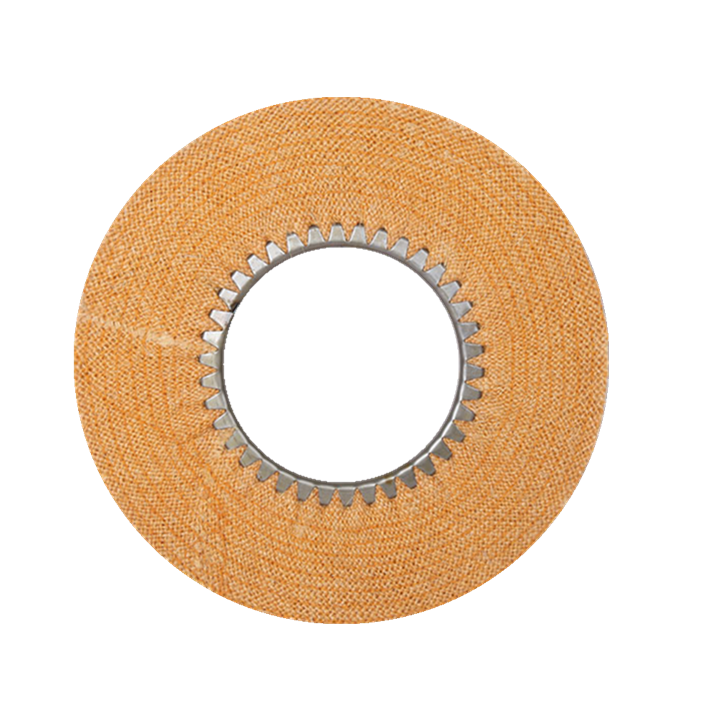

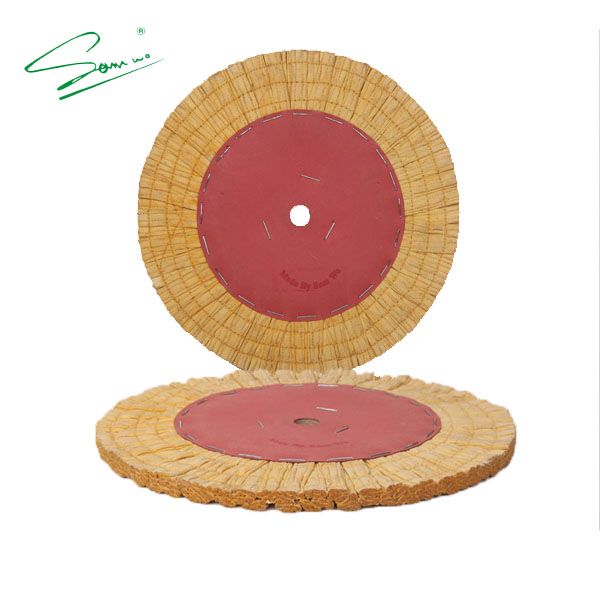

BS001

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS002

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds. Bias Sisal Buff (BS)

BS003

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS004

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS005

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS006

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS007

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS008

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS001

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS002

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds. Bias Sisal Buff (BS)

BS003

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS004

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS005

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS006

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS007

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

BS008

Conventional sisal disc buff with bias cut, is suitable for cutting operation and polishing of flat or contoured surface. With the sisal threads run at 45°to the contact surface and through dip treatment in special resin, they have high cutting power, great production for per buff, long service life, and can save polishing compounds.

FS001

Bundles of sisal wrapped by cotton cloth, followed by dip treatment in resins after sewing, they are suitable for pre-polishing of the flat and irregular contoured surface. High cutting power, good elasticity and long service life are their advantages.

FS002

Bundles of sisal wrapped by cotton cloth, followed by dip treatment in resins after sewing, they are suitable for pre-polishing of the flat and irregular contoured surface. High cutting power, good elasticity and long service life are their advantages.

FS003

Bundles of sisal wrapped by cotton cloth, followed by dip treatment in resins after sewing, they are suitable for pre-polishing of the flat and irregular contoured surface. High cutting power, good elasticity and long service life are their advantages.

FS004

Bundles of sisal wrapped by cotton cloth, followed by dip treatment in resins after sewing, they are suitable for pre-polishing of the flat and irregular contoured surface. High cutting power, good elasticity and long service life are their advantages.

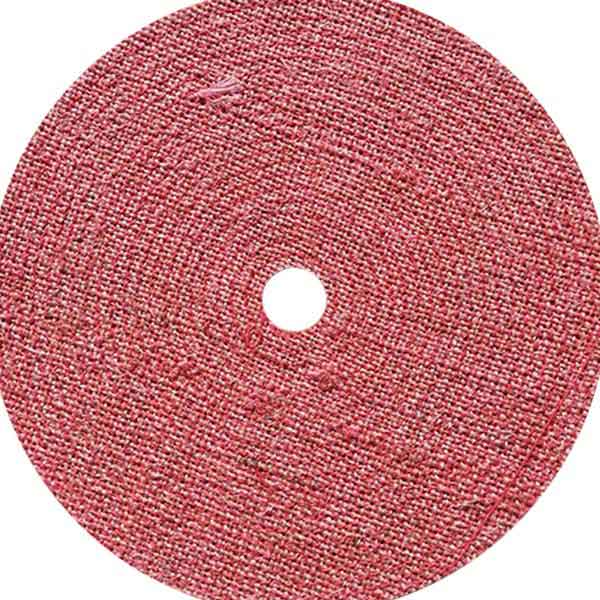

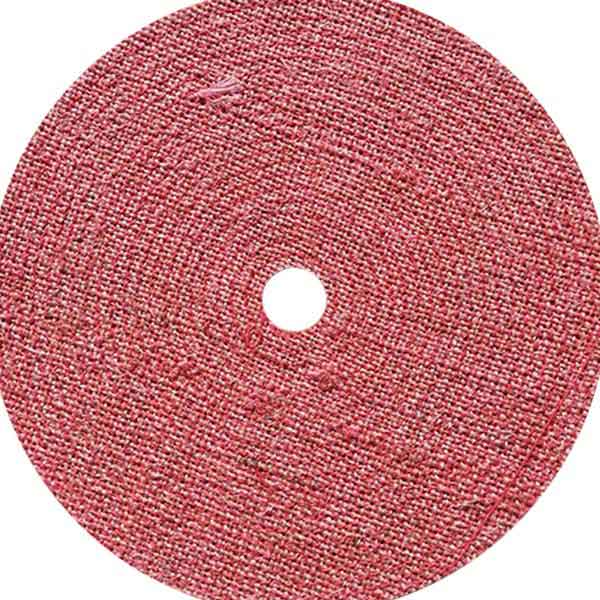

DS001

With sisal layers, or cloth layers and sisal layers stitched to each other to the desired thickness, these buffs are suitable for flat surface buffing, both in manual and automatic operation. Cotton interleaves improve the polishing performance. Long service life, good retentionof polishing compounds, and high cutting power are preferable.

DS002

With sisal layers, or cloth layers and sisal layers stitched to each other to the desired thickness, these buffs are suitable for flat surface buffing, both in manual and automatic operation. Cotton interleaves improve the polishing performance. Long service life, good retentionof polishing compounds, and high cutting power are preferable.

DS003

With sisal layers, or cloth layers and sisal layers stitched to each other to the desired thickness, these buffs are suitable for flat surface buffing, both in manual and automatic operation. Cotton interleaves improve the polishing performance. Long service life, good retentionof polishing compounds, and high cutting power are preferable.

OS002

One Layer of bias sisal sewed with two layers of cotton cloth, provides it good cutting and polishing properties, mainly used for pre-polishing of metal ware.

OS003

One Layer of bias sisal sewed with two layers of cotton cloth, provides it good cutting and polishing properties, mainly used for pre-polishing of metal ware.

OS004

One Layer of bias sisal sewed with two layers of cotton cloth, provides it good cutting and polishing properties, mainly used for pre-polishing of metal ware.

OS005

One Layer of bias sisal sewed with two layers of cotton cloth, provides it good cutting and polishing properties, mainly used for pre-polishing of metal ware.

OS006

One Layer of bias sisal sewed with two layers of cotton cloth, provides it good cutting and polishing properties, mainly used for pre-polishing of metal ware.

OS007

One Layer of bias sisal sewed with two layers of cotton cloth, provides it good cutting and polishing properties, mainly used for pre-polishing of metal ware.

OS008

One Layer of bias sisal sewed with two layers of cotton cloth, provides it good cutting and polishing properties, mainly used for pre-polishing of metal ware.

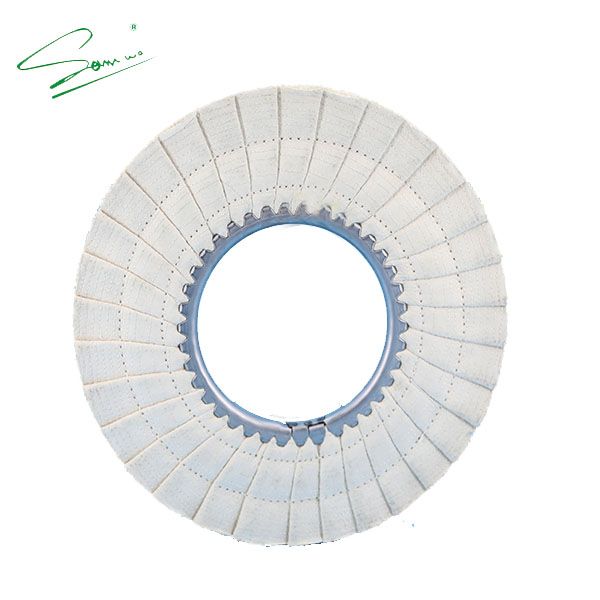

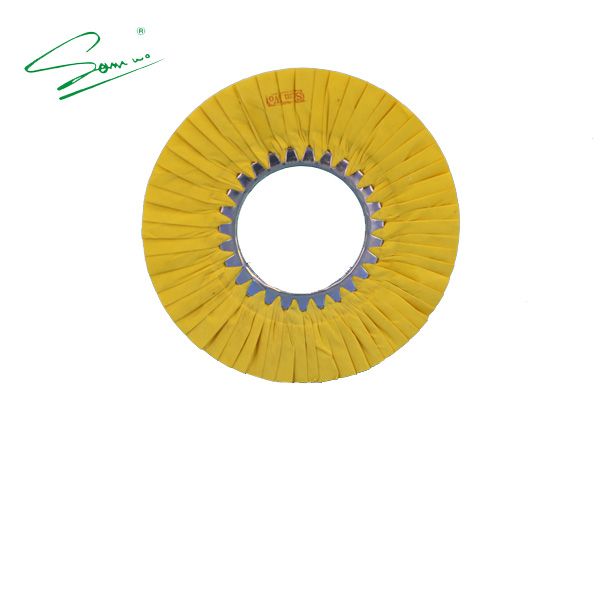

Bias Cloth Buff (BC)

Pure cotton cloth ruffled regularly or irregularly, they are\nsuitable for fine polishing of irregularly-shaped metal ware,\ndie casting, plastics, laquer and wood. Non-streak polishing;\ngood retention of polishing compounds; self-cooling in operation.\nThey are applied in both manual and automatic polishing.\nAccording to the production technics, we divide them into\nthree main types: W type, Z type, and open type.

BCW001

Having been impregnated, these wave -formed cotton cloth buffs are harder. They are the most economical and multi-functional buffs, suitable for cutting and semi-polishing of the surface.

BCZ001

Regular pleats lead to self-cooling; these buffs are extremely\nflexible and very suitable for the polishing of heavily shaped\nitems such as sanitary fittings, builders hardware, hollow wares.

BCZ002

Regular pleats lead to self-cooling; these buffs are extremely flexible and very suitable for the polishing of heavily shaped items such as sanitary fittings, builders hardware, hollow wares.

BCZ003

Regular pleats lead to self-cooling; these buffs are extremely flexible and very suitable for the polishing of heavily shaped items such as sanitary fittings, builders hardware, hollow wares.

BCZ004

Regular pleats lead to self-cooling; these buffs are extremely flexible and very suitable for the polishing of heavily shaped items such as sanitary fittings, builders hardware, hollow wares.

BCZ005

Regular pleats lead to self-cooling; these buffs are extremely flexible and very suitable for the polishing of heavily shaped items such as sanitary fittings, builders hardware, hollow wares.

BCZ006

Regular pleats lead to self-cooling; these buffs are extremely flexible and very suitable for the polishing of heavily shaped items such as sanitary fittings, builders hardware, hollow wares.

BCZ007

Regular pleats lead to self-cooling; these buffs are extremely flexible and very suitable for the polishing of heavily shaped items such as sanitary fittings, builders hardware, hollow wares.

BCZ008

Regular pleats lead to self-cooling; these buffs are extremely flexible and very suitable for the polishing of heavily shaped items such as sanitary fittings, builders hardware, hollow wares.

BCO001

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO002

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO003

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO004

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO005

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO006

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO007

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO008

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO009

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO0010

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO0011

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

BCO0012

The following Bias Cloth Buffs are Open Type. Slightly corrugated and irregularly folded, these buffs are suitable for polishing of any accessible flat surface, for pre-polishing and finishing of flat or irregular surface.

PW001

Formed by intercrossing layers of cotton cloth, sewed spirally with cotton thread, these buffs are suitable for polishing of any accessible flat surface, as a set-up wheel with glue and abrasive emery.

PW002

Formed by intercrossing layers of cotton cloth, sewed spirally with cotton thread, these buffs are suitable for polishing of any accessible flat surface, as a set-up wheel with glue and abrasive emery.

PW003

Formed by intercrossing layers of cotton cloth, sewed spirally with cotton thread, these buffs are suitable for polishing of any accessible flat surface, as a set-up wheel with glue and abrasive emery.

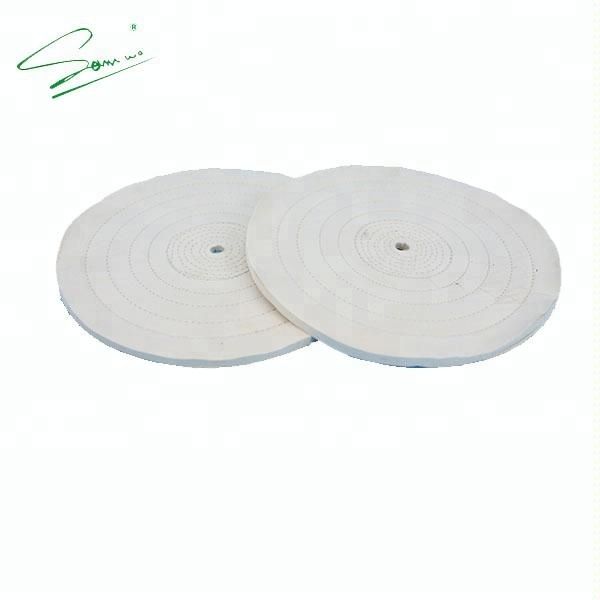

DC001

Formed by sewing layers of pure cotton cloth, they are universal buffs for common polishing machines to polish the flat surface. High luster finish, good retention of polishing compounds and long service life are their advantages.

DC002

Formed by sewing layers of pure cotton cloth, they are universal buffs for common polishing machines to polish the flat surface. High luster finish, good retention of polishing compounds and long service life are their advantages.

DC003

Formed by sewing layers of pure cotton cloth, they are universal buffs for common polishing machines to polish the flat surface. High luster finish, good retention of polishing compounds and long service life are their advantages.

DC004

Formed by sewing layers of pure cotton cloth, they are universal buffs for common polishing machines to polish the flat surface. High luster finish, good retention of polishing compounds and long service life are their advantages.

DC005

Formed by sewing layers of pure cotton cloth, they are universal buffs for common polishing machines to polish the flat surface. High luster finish, good retention of polishing compounds and long service life are their advantages.

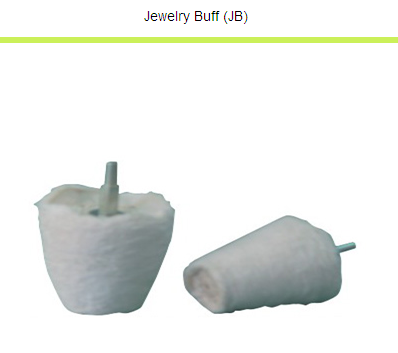

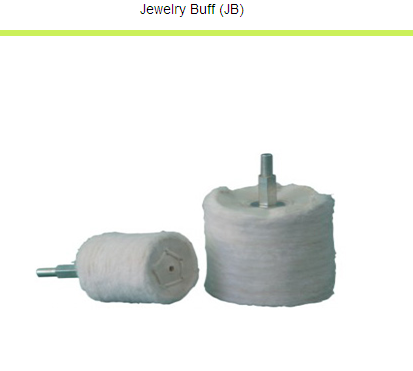

JB001

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB002

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB003

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB004

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB005

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB006

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB007

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB008

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB009

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB010

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB011

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB012

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB013

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

JB014

Formed by sewing layers of pure cotton cloth, and leather core available if required, these buffs are suitable for fine polishing of various jewelries made of brass, silver, gold or etc.

ES001

Made of eight strands trimmed African sisal yarn, \nthese buffs can polish the inner surface of table wares,\nwater tanks and locks when used in manual, semi-\nautomatic or automatic machines. Excellent flexibility; able\nto polish the inner area; high cutting power; self-\ncooling during operation.

ES002

Made of eight strands trimmed African sisal yarn, \nthese buffs can polish the inner surface of table wares,\nwater tanks and locks when used in manual, semi-\nautomatic or automatic machines. Excellent flexibility; able\nto polish the inner area; high cutting power; self-\ncooling during operation.

ES003

Made of eight strands trimmed African sisal yarn, \nthese buffs can polish the inner surface of table wares,\nwater tanks and locks when used in manual, semi-\nautomatic or automatic machines. Excellent flexibility; able\nto polish the inner area; high cutting power; self-\ncooling during operation.

ES004

Made of eight strands trimmed African sisal yarn, these buffs can polish the inner surface of table wares,water tanks and locks when used in manual, semi-automatic or automatic machines. Excellent flexibility; able to polish the inner area; high cutting power; self-cooling during operation.

ES005

It is woven with eight strands of cut African hemp yarn and used with manual, semi-automatic or full-automatic machine to grind the deep image of tableware, sink, lock, etc. The utility model has the advantages of excellent elasticity, deep concave position, high cutting force and self cooling in operation.

ES006

It is woven with eight strands of cut African hemp yarn and used with manual, semi-automatic or full-automatic machine to grind the deep image of tableware, sink, lock, etc. The utility model has the advantages of excellent elasticity, deep concave position, high cutting force and self cooling in operation.

ES007

It is woven with eight strands of cut African hemp yarn and used with manual, semi-automatic or full-automatic machine to grind the deep image of tableware, sink, lock, etc. The utility model has the advantages of excellent elasticity, deep concave position, high cutting force and self cooling in operation.

ES008

It is woven with eight strands of cut African hemp yarn and used with manual, semi-automatic or full-automatic machine to grind the deep image of tableware, sink, lock, etc. The utility model has the advantages of excellent elasticity, deep concave position, high cutting force and self cooling in operation.

ST001

It is woven from two strands of cut African hemp yarn, which is softer and more elastic than other hemp wheels. Compared with other hemp wheels, it has the same cutting effect, with the advantages of excellent elasticity, wide cutting surface and deep concave position.

ST002

It is woven from two strands of cut African hemp yarn, which is softer and more elastic than other hemp wheels. Compared with other hemp wheels, it has the same cutting effect, with the advantages of excellent elasticity, wide cutting surface and deep concave position.

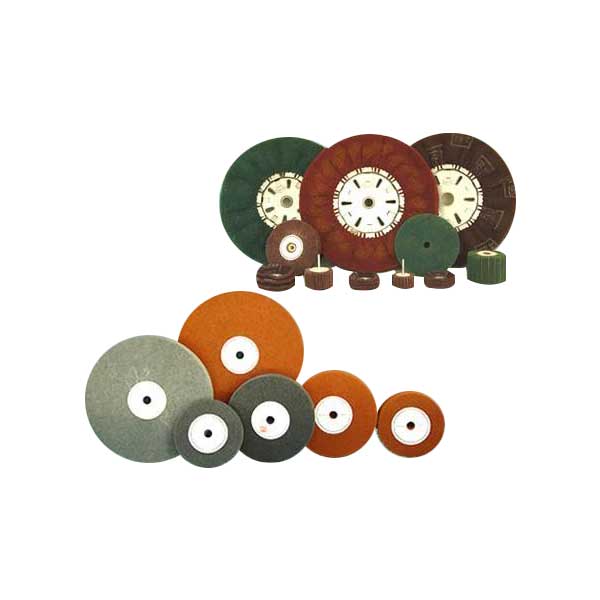

FB001

Fiber wheel (FB)

FB002

Fiber wheel (FB)

FB003

Fiber wheel (FB)

FB004

Fiber wheel (FB)

FB005

Fiber wheel (FB)

FB006

Fiber wheel (FB)

FB007

Fiber wheel (FB)

NW001

Made of nylon yarn with abrasive emery,these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW002

Made of nylon yarn with abrasive emery,these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control

NW003

Made of nylon yarn with abrasive emery,these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control

NW004

Made of nylon yarn with abrasive emery,these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW005

This kind of nylon brush is made of nylon wire with abrasives. It is a kind of highly effective polishing agent specially developed by our company. Compared with the traditional fiber brush used for water tank polishing, this new type of nylon brush is more economical and durable.

NW006

Made of nylon yarn with abrasive emery,these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW007

Made of nylon yarn with abrasive emery,these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW008

Made of nylon yarn with abrasive emery, these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW009

Made of nylon yarn with abrasive emery, these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW0010

Made of nylon yarn with abrasive emery, these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW0011

Made of nylon yarn with abrasive emery, these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW0012

Made of nylon yarn with abrasive emery, these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

NW0013

Made of nylon yarn with abrasive emery, these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

Nylon belt

Nylon Belt(NBT) Nylon belt,also known as non-woven belt,with the characteristics of fiber as the substrate, with the three-dimensional structure of strong elastic plasticity, suitable for satin precision grinding of all kinds of stainless steel tableware,steel,aluminum and other metal.

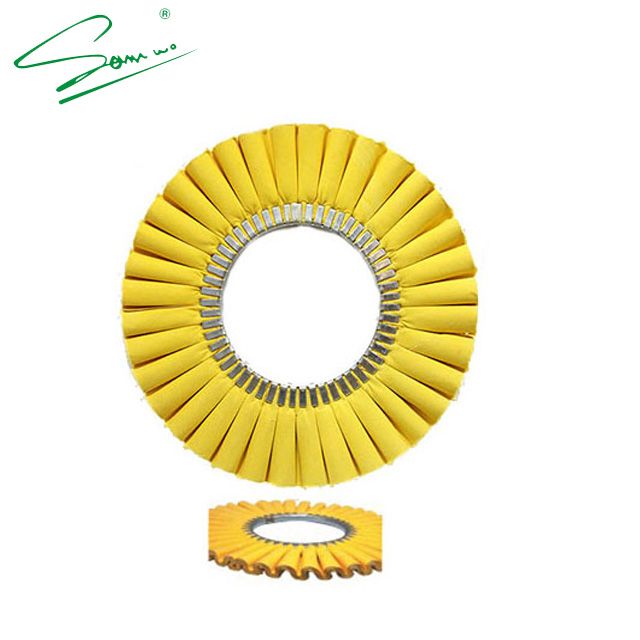

FW001

Flap Wheel(FW)Characteristics and functions are similar with that of the FD.Both are adopted in the process of dust removal, finishing and polishing.But FW is mainly used in automatic machines operation

FW002

Flap Wheel(FW)Characteristics and functions are similar with that of the FD.Both are adopted in the process of dust removal, finishing and polishing.But FW is mainly used in automatic machines operation.

FW003

Flap Wheel(FW)Characteristics and functions are similar with that of the FD.Both are adopted in the process of dust removal, finishing and polishing.But FW is mainly used in automatic machines operation.

FW004

Flap Wheel(FW)Characteristics and functions are similar with that of the FD.Both are adopted in the process of dust removal, finishing and polishing.But FW is mainly used in automatic machines operation.

FW006

Flap Wheel(FW)Characteristics and functions are similar with that of the FD. Both are adopted in the process of dust removal, finishing and polishing.But FW is mainly used in automatic machines operation.

Wool felt wheel (WF)

Wool Felt Buff(WF) Made of specially treated pure wool, it's used for buffing of electroplated metal articles to bronze colour. Especially suitable for polishing metal gifts and metal spectacle frames. Great flexibility, durable;faster finishing.The sizes and the density of the buff is up to customers' requirement.

Wire wheel (WB)

Wire Brushes(WB) Made of steel wire,this brush is very sharp in cutting and deburring but very flexible in reaching each corner of work pieces,mainly applicated in the first process of cutleries surface deburring and smoothing.

Nylon Brush 01

Made of nylon yarn with abrasive emery,these brushes are newly developed by our company,specially for kitchen sink polishing.Comparing with the traditional tampico fiber brushes,these nylon brushes are more economical,in terms of polishing efficiency,durability and cost control.

Center iron plate CP

Centre Plate(CP) Centre plate can be tailor-made according to the shaft's diameter of customer's machine.

Abrasive polish (PC)

In addition to grinding wheel, we also produce all kinds of solid and liquid polishing agents to fully meet the needs of customers. They are used with all kinds of grinding wheels and are suitable for surface treatment of all metal, plastic paint and wood.

G-14

For fine polishing, use cooperatively with cloth buff, high luster finish effect can be achieved by using G-14. They are usually applied to polishing stainless steel, etc.

SW-1

For cutting &rough polishing, use cooperatively with Sisal Buff. They have the specialty of strong cutting ability.

SW-3

Rough polishing. use cooperatively with Sisal Buff, with 70% of cutting ability and 30% of polishing ability. They are suitable for polishing all kinds of metals.

SW-2000

For rough polishing, use cooperatively with Sisal Buffs. Suitable for polishing soft metals like aluminum, zinc, etc.

Abrasive Emery(AE)

Abrasive Emery(AE) Brown Aluminium Oxide(A),White Aluminium Oxide(WA), Black Aluminium Oxide(BA), Zirconia Aluminium Oxide(ZA), Pink Aluminium Oxide(PA), Black Silicon Carbide(C), Green Silicon Carbide(GC), etc.

Sisal cloth

Sisal cloth is mainly used for polishing wheel production and carpet industry. According to these two applications, our sisal cloth can be made of sisal materials of African origin, Chinese origin and Brazil origin; density, weight per square meter and width can be tailor-made according to customers' special demand.

Sisal Twine

Our sisal twine can be made of 1-7 sisal yarns of 350-1200m/kg(African origin, Chinese origin and Brazil origin), widely used for industrial & gift packing, gardening tools,household tools, etc. Regular specifications are shown at the table of next page.

Sisal Yarn

SW-DNK1300 single axis automatic bending machine

This machine is suitable for the polishing of cutlery intrados and other similar shape products

SW-DNK1310Single-Shaft Automatic Polishing Machine with 2 Working Desks

SW-DNK1310 is mainly designed for the edge grinding and polishing of cutlery(knives,forks and spoons)

SW-DNS-1301 single axis steam edging machine

This machine is suitable for the grinding and polishing of stainless steel forks and spoons

SW-DYK1300Single Shaft Automatic Machine for Cutlery Periphery

This machine is specially for the periphery area polishing of stainless steel fork, spoon and other similar surface products

SW-S1300 double shaft automatic inner and outer bending machine

This machine is specially designed for the polishing of stainless steel spoons, intrados and periphery at the same time. It works very well at precise polishing.

SW-SPK1300 double axis automatic plane polishing machine

This machine is suitable for the plain surface polishing of stainless steel cutlery, hardware, glasses and electriplated products.

What you care about is information

SAM WO